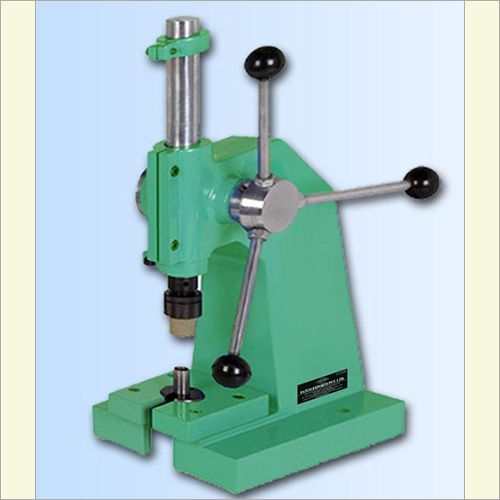

Bobbin Roving End Opening Machine

Product Details:

- Material Mild Steel

- Automatic Grade Semi-Automatic

600000 INR/Unit

X

Bobbin Roving End Opening Machine Price And Quantity

- 1 Unit

- 600000 INR/Unit

Bobbin Roving End Opening Machine Product Specifications

- Semi-Automatic

- Mild Steel

Bobbin Roving End Opening Machine Trade Information

- 15 Days

Product Description

A Bobbin Roving End Opening Machine is an industrial machine used in the textile industry to open and prepare roving ends for further processing. It plays a crucial role in ensuring the smooth and efficient flow of roving during yarn production.

Q: How does a Bobbin Roving End Opening Machine work?

A: The Bobbin Roving End Opening Machine receives bobbins filled with roving, which are yarns that have been twisted and partially spun. The machine processes the roving ends by opening and aligning the fibers, removing any tangles or inconsistencies, and preparing them for subsequent yarn spinning operations.

Q: What are the main components of a Bobbin Roving End Opening Machine?

A: A typical Bobbin Roving End Opening Machine consists of a creel or bobbin holder for accommodating multiple bobbins, a drafting system for controlling the tension and speed of the roving, and various mechanisms for opening and preparing the roving ends.

Q: What is the purpose of a Bobbin Roving End Opening Machine?

A: The primary purpose of a Bobbin Roving End Opening Machine is to prepare the roving ends for further processing in the yarn production process. By opening and aligning the fibers, it ensures a consistent and well-prepared feed of roving, leading to improved yarn quality and production efficiency.

Q: Can a Bobbin Roving End Opening Machine handle different types of roving?

A: Yes, Bobbin Roving End Opening Machines are designed to handle various types of roving made from different fibers, such as cotton, wool, synthetic fibers, or blends. The machine can be adjusted and set up to accommodate the specific characteristics of the roving being processed.

Q: Is the Bobbin Roving End Opening Machine an automated machine?

A: Yes, modern Bobbin Roving End Opening Machines are typically automated, equipped with advanced controls and features. They may include computerized systems for precise adjustments, monitoring sensors for quality control, and automation for efficient roving processing.

Enter Buying Requirement Details